Find Your Best Steel Supply Deals Today

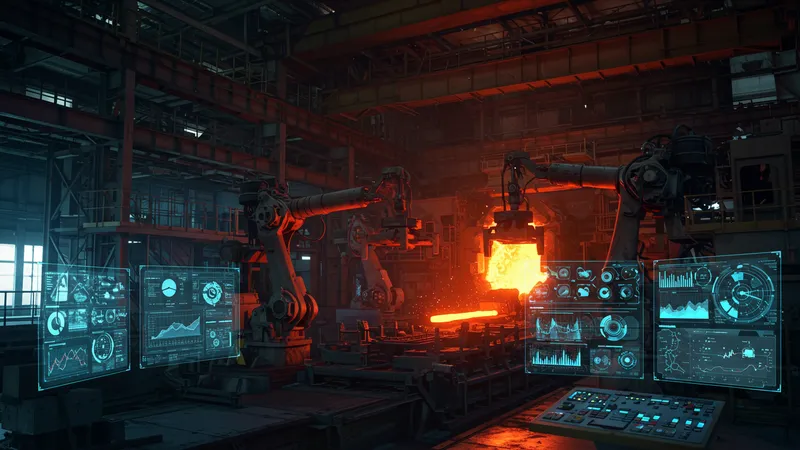

The Role of AI and Automation in Steel Efficiency

Artificial Intelligence has infiltrated the steel industry, bringing unparalleled efficiency and precision in production and distribution. Tasks traditionally done by human oversight now benefit from AI’s error-free consistency and rapid automation capabilities.

AI-powered monitoring systems predict and preempt equipment wear and tear, drastically reducing maintenance woes and downtime. These proactive approaches ensure greater life cycles for machinery and materials alike. Yet, the full breadth of AI’s prowess isn’t entirely realized…

The shift towards AI also redefines labor dynamics. While skepticism suggests AI could replace jobs, what emerges instead is an ecosystem where human oversight enhances tech-driven operations. New roles and fields of expertise sprout rapidly to accompany innovation. It’s not all smooth sailing, though…

Implementation barriers, ranging from technological literacy to infrastructure adjustment costs, demand swift addressal. Automation holds promises of heightened efficacy but also pushes firms towards adaptation—a double-edged sword if unprepared. Another variable complicates this further…